An emerging technology, robotic process automation (RPA), is fast becoming the go-to way for improving competency in the energy sector. The mundane and repetitive day-to-day jobs can be offloaded to RPA, freeing up manpower.

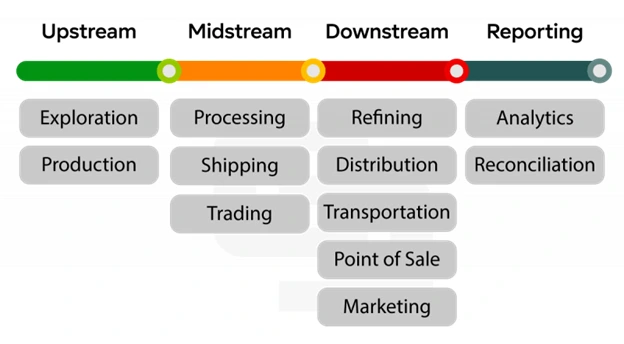

The oil and gas companies, irrespective of their hierarchy in the pipeline (upstream, midstream or downstream) are subject to uncertainties and business operating pressures. Some of the factors cannot be combated easily and have to be taken into account.

Here, we take a look at the major factors such as:

- What is RPA?

- How RPA can assist the oil and gas sector

- What are the in-chain processes that can benefit from automation?

The International Energy Agency, in a 2018 report, stated that the oil and gas industry has experienced an upswing, with positive cash flow improving due to better oil prices, lower interest rates, and cross-industry consolidations.

The International Energy Agency, in a 2018 report, stated that the oil and gas industry has experienced an upswing, with positive cash flow improving due to better oil prices, lower interest rates, and cross-industry consolidations.

Impact of Automation on Oil and Gas sector

The oil and gas sector is gradually incorporating Intelligent Business Process Automation. Robotic Process Automation or RPA deploys bots that can take on many daily routine tasks that adhere to specific guidelines. Outsourcing these mundane tasks to robots can help save time and effort, thereby enhancing the company's productivity.With the onset and ongoing Covid pandemic, energy prices are witnessing a downward slide. The demand for oil and gas is decreasing. In this scenario, many companies are faced with the issue of achieving profitability when the demand and prices are slipping.

With technology and automation entering every industry to maximize processes and outputs, it is then of paramount importance that a crucial sector like the Oil and Gas industry not lag behind in upgrading its systems and processes.

It is an ideal time for the oil and gas industry to adapt to Robotic /Intelligent Process Automation, and take advantage of the benefits and derive maximum gain from infrastructure and resources.

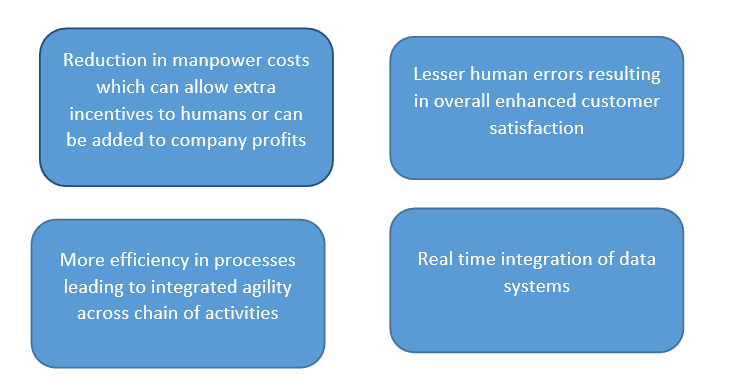

RPA will enable better integration in business operations, making them more lean and agile, and will enable access to data on a real-time basis, thereby improving productivity and enhancing profitability in the long run.

RPA for Upstream Oil and Gas activities

Activities like drilling have undergone many changes to be able to be more efficient and supple. The new buzzword in drilling has been pad drilling. It has become a benchmark in drilling operations and has shown great results in shale-rich deposit areas. However, with the latest efficient methods, the configuration also needs to be precise. The oilfield drilling service providers need to assess and configure the exact drilling spots as there is no scope for error. In such an ecosystem, real-time integration and field management are crucial as they lead to improved forecasting.

RPA for Midstream Oil and Gas activities

As the underground technologies have improved drilling outputs, parallel improvements in the supervisory control and data acquisition systems (SCADA) have provided immense benefits to the companies.

Though the output in production is showing an improvement, the midstream activities of transportation and shipping are being tested. An upside to this is that new infrastructure is being developed. This is the ripe time for companies to invest in an automation ecosystem that integrates Business Process Management with specialized Robotic Processes.

RPA for Downstream Oil and Gas activities

As downstream processes are increasing in complexity, RPA can aid in enhancing productivity. Many processes in back-office work, such as invoicing, generating quotes, shipping, reporting, etc., can be outsourced to Automation.

As the Oil and gas energy sector is prone to many fluctuations, RPA should be a crucial feature to increase productivity across all chains, be it upstream, mid, or downstream. With the multi-benefits of reducing mundane tasks and thereby enhancing accuracy, energy companies can work on more efficient work cycles, leading to more resource management and efficiency in their organizations.

Robotic Process Automation Benefits

Conclusion

Conclusion

Integrating robotic process automation into your company, if you are from the energy sector, will enable you to avail all the benefits. Faster turnaround service time and major cost benefits will impact your bottom line in the long run.

A thorough analysis will enable you to strategize and prioritize. A phase-by-phase automation implementation should be carried out. After budgetary and team allocation, you need to decide on the appropriate RPA technology that will be best suited to your specific needs.

Intelligent Process Automation will become more and more important in a post-COVID environment as businesses save on time, money, and need to be more resilient and geared to meet the new demands. Technology will be the key determinant in the survival and prosperity of many businesses.

Let's Discuss Your Idea.!

Whether you have a question for our team, want to chat about your project ideas, or are curious about our expertise, please send us your request using the form below.

Contact Info

Our contacts