SIGVARIS is a Medical

Equipment

Manufacturing group based in the Peachtree City, GA USA. Sigvaris offers high quality and

innovative medical compression solutions that improve health and well being.

Manufacturing

As SIGVARIS GROUP, we are a reliable and experienced partner to our customers around the

world which include Pharmacies, DME, Orthopedic and Medical Specialist stores as well as

Medical Professionals and Hospitals. They advise individuals and provide them with products

and solutions for medical compression.

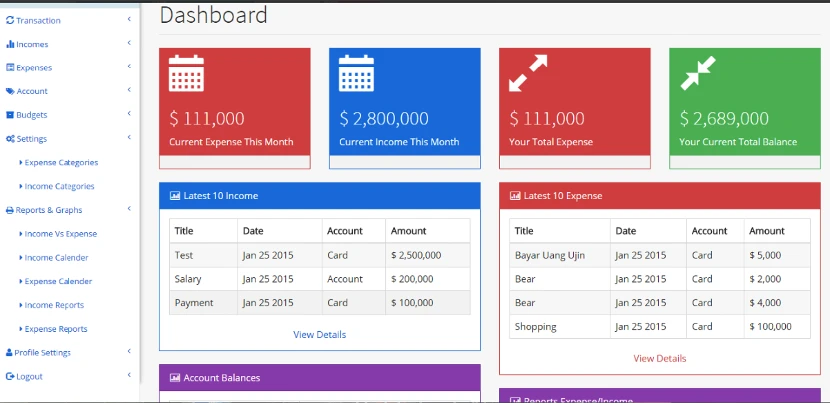

As the previous

system was

outdated, and difficult to use. SIGVARIS GROUP was looking to build a CRM system software

with modern technology to manage the sales process, track customers and manage their order

history. Streamline the sales process by easily identifying business opportunities and new

leads.

As the previous

system was difficult to use, when the DigiPrima Expert team began the search for a

replacement system, the most important factor was the simplicity of the new system.